A custom steel sculpted universal connector at the top of the glulam support columns was developed to accommodate the constantly varying roof geometry.

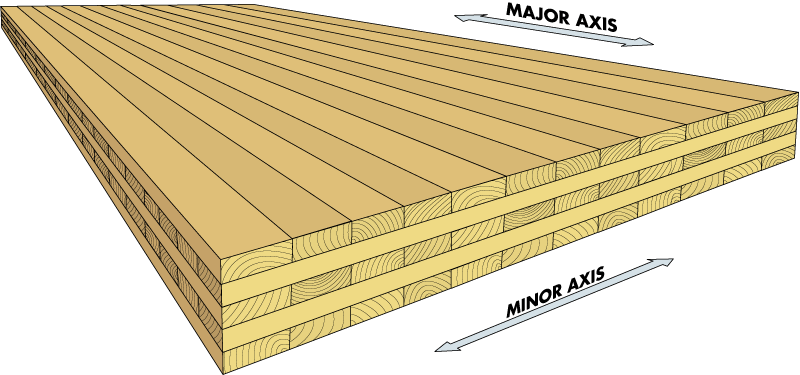

Solid laminated roof diaphragm.

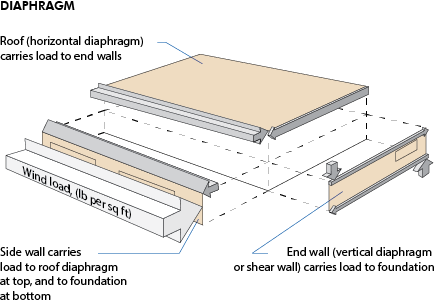

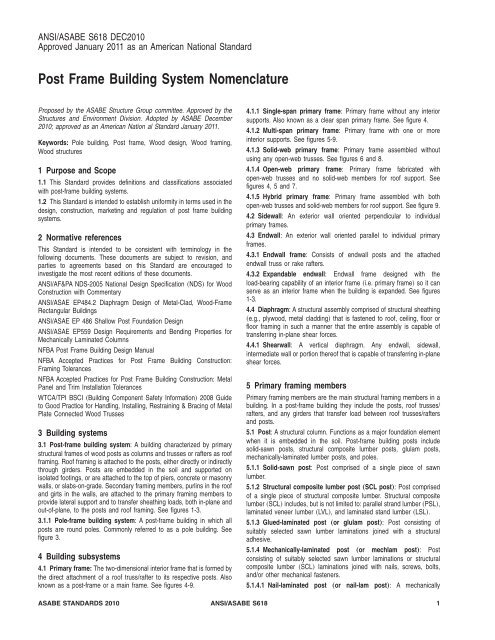

A diaphragm is a flat structural unit acting like a deep thin beam.

Asce 7 american society of civil engineers.

Or thicker or laminated decking.

A shear wall however is a vertical cantilevered diaphragm.

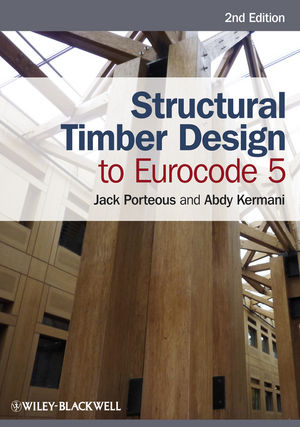

Application of elastomeric adhesives to the tongue and groove joints between solid or laminated timber decking can greatly increase the strength and stiffness of roof diaphragms 35 72.

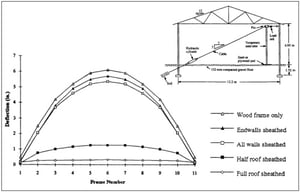

Buildings that have primary wood frames with no lateral rigidity columns simply supported at top and bottom depend entirely on the diaphragm shear wall system for.

Nail laminated timber nlt.

Decking is also available in laminated wood.

Irc table r803 1 lists 1 1 2 t g for rafter spans up to 72.

The ibc icc 2003a and the af pa 2005 permit wood structural panel diaphragm sheathing to be fastened over solid lumber planking or laminated decking using full tabulated values for new construction.

Goodfellow also offers solid wood decking species in red pine red cedar spruce and larch.

Construction adhesives for field gluing plywood to wood framing must meet minimum performance standards specified in astm d 3498 10.

Inherent is the assumption that the sheathing nail will have a penetration of not less than 10 diameters.

Tall wood buildings like t3 minneapolis have used nlt as floor and roof panels atop glulam beams.

The term diaphragm is usually applied to roofs and floors.

Design and detailing of plywood floor and roof diaphragms.

The roof diaphragm functions as a horizontal medium through which lateral forces are collected and redistributed to each participating vertical element wood frame shear walls.

It is designed of two to five strips of kiln dried wood glued with an exterior waterproof adhesive to form a glulam roof decking.

I am looking to space rafters at 72 however i cannot find any information on diaphragm strength of the t g decking.

This project features a free form solid laminated wood roof site fabricated with 2 x 6 lumber in six foot wide panels and supported by 93 milled glulam columns and a two way cable truss system.

Does anyone have experience using tongue and groove decking for roof sheathing.

Minimum design loads for.

These construction systems can be used when designing a building for lateral loads such as those generated by wind or earthquakes.